Gold plating with jewelry plating machine is an easy technique, but before beginning the process, make sure your plater follows the best practices for best plating results.

Step 1: Surface Preparation

The surface of the metal to be plated must be very clean, so oils or dirt must be removed, and the piece must be polished. Surface preparation can include stripping, polishing, sandblasting, tumbling, etc. The use of solvents, abrasive materials, alkaline cleaners, acid etch, water, or a combination can be used. Typical methods to clean include acid or non-acid ultrasonic bath and a high rpm rouge wheel polishing. This is necessary for two reasons:

To improve adherence. (Dust and dirt interfere with the plated metals adhering to the jewelry piece.)

To keep the plating tanks free of contaminants.

Step 2: Cleaning

After the surface is prepared, and a visual inspection is done, electrocleaning, ultrasonic cleaning, or steaming, usually takes place. This second, deeper, cleaning step must follow to ensure metal is free of oils and dirt, which helps produce superior plating results. Steam cleaning blasts off any remaining oils that managed to hang on during the polishing phase. Take special note of intricate jewelry that has many nooks and crannies.

Step 3: Rinse

The piece is rinsed thoroughly with water to remove any cleaning agents.

Step 4: Strike

A strike layer — also called a flash layer — adheres a thin layer of high-quality nickel plating to the base metal.

In order to improve the bonding between the plating and the underlying surface, occasionally a buffer layer must be applied between them. With costume jewelry the base metal would contaminate the tanks with the gold in them, so a different metal is plated prior to the gold plating.

Additionally this step is used when the base metal, like copper, is known to atomically migrate outside of the gold layer to create spots of tarnish after plating. This strike step creates a barrier between the reactive base metal and the plated metal. This extends the life of the bright gold plating.

Step 5: Rinse Again

The piece is rinsed thoroughly with water to remove any cleaning agents.

Step 6: Base Coat

If a base coat below gold is used, it is usually nickel.There can be many layers of plating done on one particular piece. For example a gold-plated silver article is usually a silver substrate with layers of copper, nickel, and gold deposited on top of it.

Step 7: Final Coating

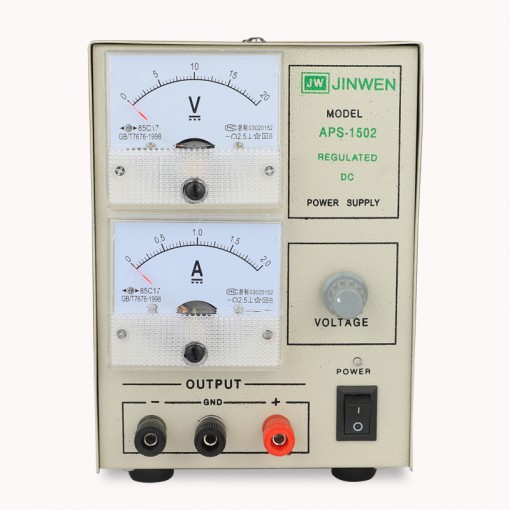

With time, temperature and voltage carefully controlled, the piece is submerged into the plating solution to attract ions of gold or the final metal that will show on the surface. Different metals require different voltages and temperatures.

The items to be plated are hung from a cathode bar, which is a pole with a negative electrical charge going through it. The pieces of jewelry connected to the cathode bar are also negatively charged. When the jewelry items are submerged in the tank an electrical charge is applied and the negatively charged jewelry attracts the positively charged ions present in the solution. The positively charged metal ions are submersed in the solution bath. When the cathode bar is lowered into the bath the metal jewelry gets plated.

The plating thickness can be controlled by adjusting the immersion time in the plating tank.

Step 8: Final Rinse

Rinse off the pieces with water and then hang them to dry.

Step 9: Drying

The pieces are hung, preferably not touching each other, in order to dry.

Step 10: Repeat – if Necessary

Occasionally, the immersion step into the chosen plating metal needs to be repeated. In order to improve the bonding between the plating and the underlying surface, occasionally a buffer layer must be applied between them.

After that step, rinsing and drying needs to be done.