Gold Electroplating with jewelry plating machine is a method of depositing a thin layer of gold onto the surface of another metal.

Gold plating finds its uses in jewelry, semiconductor industry. It often employed in electronics to provide a corrosion resistant surface.

In this instructable, I am making alkaline gold plating solution which can deposit gold by electrolysis.

Traditionally, such a solutions prepared using extremely poisonous cyanide compounds which are reasonably restricted.

My goal is to make the solution with the publically available chemicals, which are not as toxic to handle. In any case, the final product will be just as poisonous as the traditionally prepared solution.

For this reason, I must warn you. This experiment is extremely dangerous, and I don’t recommend anyone without experience to repeat it.

Step 1: Nitric Acid.

If you already have nitric acid at the concentration 50% or above, you may skip this step.

In order do dissolve gold, we will need to prepare aqua regia. It is a mixture of nitric and hydrochloric acid at molar ratio 1/3. Hydrochloric acid sold commercially under the name of muriatic acid. However, nitric acid is restricted for public use. Therefore it has to be prepared from available chemicals.

Step 2: Making Gold(III)Chloride

To make gold chloride, we need to dissolve gold in aqua regia. (mixture of nitric acid and hydrochloric acid at molar ratio 1/3).

Step 3: Final Step, Making Gold Plating Solution.

In the final step, we need to make a strongly alkaline solution of gold chloride and potassium ferrocyanide.

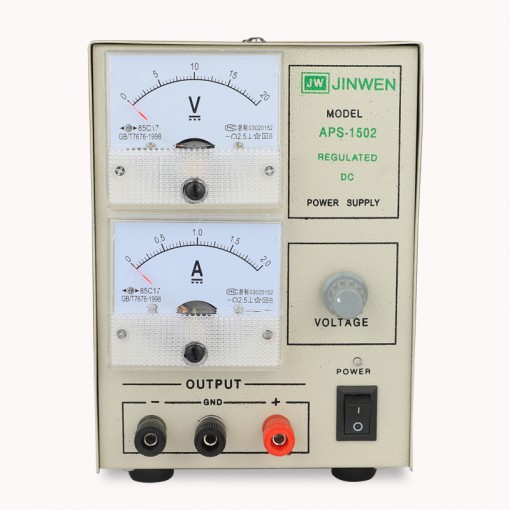

Using this solution and electrical current, we can deposit gold over the surface of other metals.

This solution contains gold cyanide ions, which are extremly poisonous.